Clean Room For Pharmaceutical Industry

There are very strict regulations for the production of medical products and drugs. Therefore, the industry’s production of medicines or various equipment needs to be processed and produced in a clean room. This can also prevent bacteria and dust in the air from adhering to the drugs, and avoid affecting the production quality of drugs due to insufficient cleanliness.

APPLICATION

Pharmaceutical

SIZE

85500 sqft

CLEANROOM CLASS

Class10000 / ISO7

Cleanliness Level

The clean room air cleanliness standards in the pharmaceutical industry are divided into four levels:

Grade A: High-risk operation areas, such as filling areas, areas where rubber stopper barrels are placed, and open packaging containers in direct contact with sterile preparations, the number of particles smaller than 0.5 microns in the air shall not exceed 3,520 per cubic meter.

Grade B: High-risk operation background areas such as aseptic preparation and filling, the number of particles smaller than 0.5 microns in the air is allowed to increase to 352,000 per cubic meter during operation.

Grade C: Clean operation areas with lower importance in the production process of sterile drugs.

Grade D: The lowest level of clean operation areas in the production process of sterile drugs.

Temperature And Humidity Requirements

The temperature of Class A, Class B, and Class C clean rooms should be controlled at 20°C~24°C, and the relative humidity should be controlled at 45%~60%.

The temperature of Class D clean rooms should be controlled at 18°C~26°C, and the relative humidity should be controlled at 45%~65%.

Air Purification System Maintenance And Management Requirements

Air purification system: should be cleaned, repaired, maintained and recorded regularly.

Indoor disinfection and floor drain cleaning: should be recorded.

Personnel management: personnel entering the clean room must change shoes, clothes, wash hands and disinfect as required, strictly control the number of personnel, regularly train staff, and supervise and register outsiders.

These standards together ensure the environmental control of clean rooms in the pharmaceutical industry, thereby ensuring the quality and safety of drug production.

Pressure Difference Standard

The static pressure difference between clean rooms of different air cleanliness levels and between clean rooms and non-clean rooms should be above 10Pa, and the static pressure difference between the clean room and the outdoor atmosphere should be greater than 10Pa.

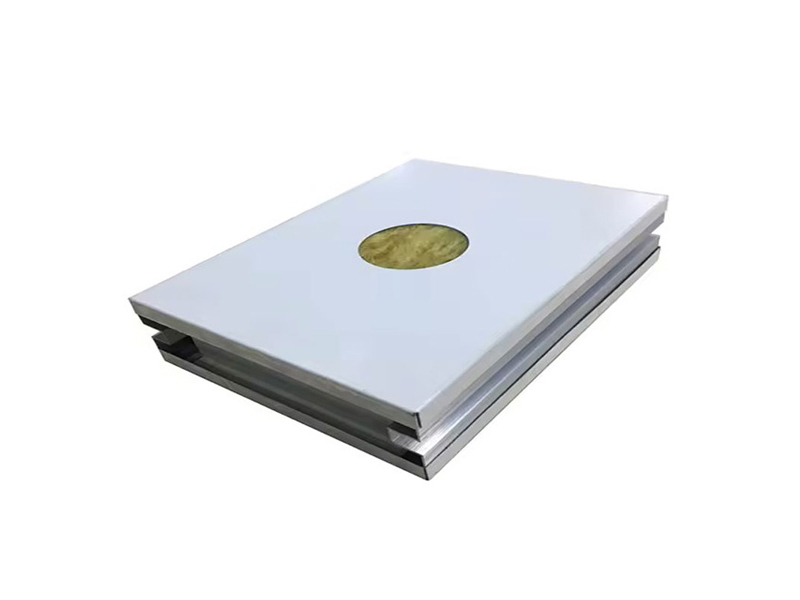

PICTURE SHOW

Clean Room Equipment

Clean Bench

Air Shower