Optical manufacturing clean room expert

Micron-level dust-free guarantee

Laser/Lens/Sensor Dedicated Clean Room · 20 Years of Industry Experience

✅ Full coverage of cleanliness levels from Class 100 to Class 100,000 | ✅ Vibration control < 0.5μm | ✅ Temperature and humidity accuracy ±0.1℃

Project Overview

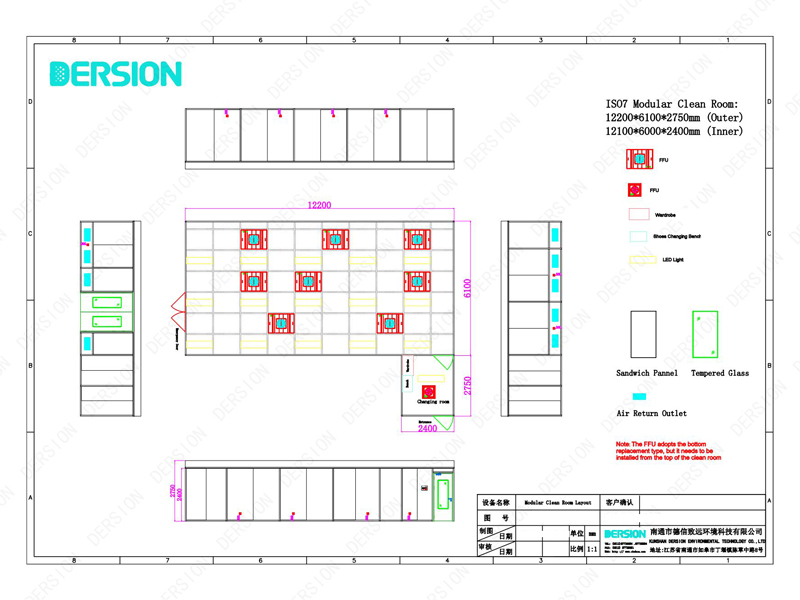

| Project Name | Construction of optical cleanroom |

|---|---|

| Customer Location | California, USA |

| Industry | Precision optical component manufacturing |

| Project Area | 124000 sqft |

| Cleanliness Level | ISO 7 (Class 10,000 cleanroom) |

| Service Content | Cleanroom design, construction, commissioning, testing and verification |

| Installation Period | 15 working days |

Special Engineering Customizations

🔹 No Glass Panel Design

To meet optical testing safety and light-isolation requirements, the cleanroom exterior was built using fully enclosed insulated metal panels — no glass walls were used. This design improves light shielding, enhances structural safety, and protects sensitive instruments.

🔹 California Seismic Compliance

The project passed California's seismic safety certification. Reinforced joints, seismic anchors, and structural bracing were used throughout. Full structural calculations and design documents were submitted and approved as required for high-seismic zones.

Project Outcomes

✔ Certified according to ISO 14644 series cleanroom standards

✔ Cleanliness level reaches ISO 7 and successfully passed third-party testing

✔ Measured particle concentration value is far better than industry standard requirements

✔ High stability of air conditioning system, temperature and humidity difference is less than ±1%

Our 6-Step Delivery Process

Ready to Build Your Precision Cleanroom?

Get Free Layout Plan

From Concept to Commissioning – We Deliver High-Performance Clean Environments.