Custom Modular Cleanrooms Built to ISO 14644 Standards

Flexible, scalable, and delivered fast. Trusted by pharmaceutical, semiconductor, and biotech industries.

Why Choose Modular Cleanrooms?

Engineered for efficiency, flexibility, and compliance.

Fast Installation

Delivered and installed in weeks, not months — minimize production downtime.

Flexible Layout

Modular panels can be customized for your room size, process flow, or equipment layout.

Standardized Manufacturing

ManufacturingAll components are prefabricated under factory standards for consistent quality.

ISO & GMP Compliant

Designed to meet ISO 14644 and GMP standards for cleanroom performance.

Scalable & Expandable

Easily expand or reconfigure your cleanroom as your business grows.

Easy Maintenance

Removable panels and simplified structure make cleaning and maintenance easier.

Industries We Serve

We deliver ISO and GMP-compliant modular cleanrooms tailored to your industry’s regulatory and operational standards.

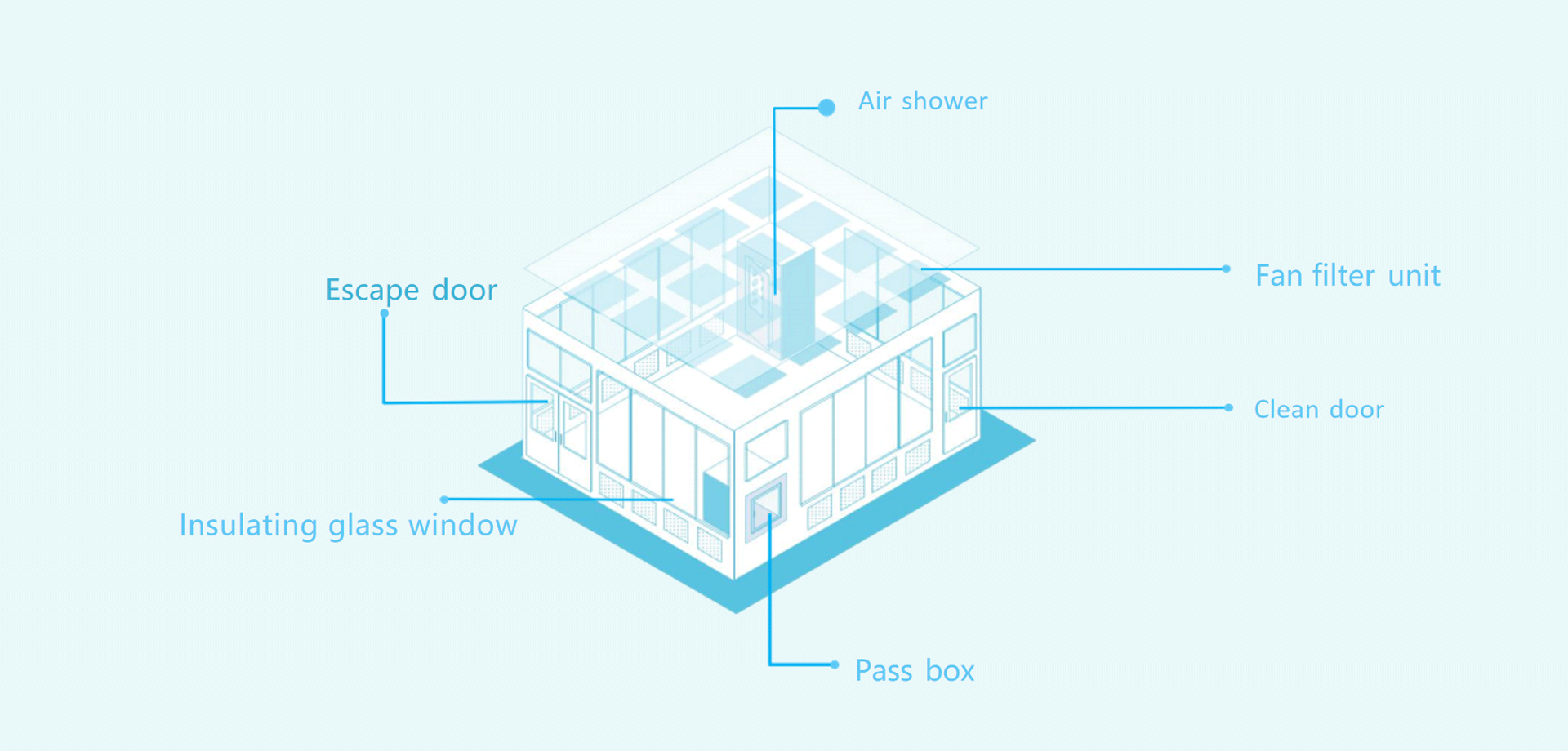

How Modular Cleanrooms Are Built

Cleanroom Customization

At DERSION, we don’t just build cleanrooms—we engineer integrated clean environments with premium materials, strict process control, and tailored solutions for critical industries. Every structural component is selected and assembled with performance, durability, and compliance in mind. Whether you’re in pharmaceuticals, electronics, optics, or aerospace, we provide a wide range of styles, materials, and technical options to meet your exact specifications.

Sandwich Panels & Aluminum Profiles

Our sandwich panels are constructed using high-grade steel skins and insulation cores (PU, EPS, or rock wool), ensuring superior thermal, acoustic, and fire resistance. Panel joints are precisely sealed to prevent air leakage. Aluminum profiles are extruded with strict tolerances, available in various anodized or powder-coated finishes to match cleanroom aesthetics. Multiple thicknesses and frame configurations are available for Class 100 to Class 100,000 environments.

Doors – Manual, Automatic, Airtight & Interlocked

We offer a full portfolio of cleanroom doors, including swing doors, sliding doors, automatic doors, and airtight interlock systems. Door leaves can be customized in stainless steel, aluminum, or double-glazed tempered glass, with options for magnetic locks, access control, and vision panels. All doors are built to prevent cross-contamination and ensure smooth operations in high-traffic areas.

Fan Filter Units (FFUs)

We design and manufacture high-efficiency FFUs equipped with HEPA or ULPA filters (H14/U15) and EC or AC fans, offering low noise, high energy efficiency, and long lifespan. Sizes range from 2x2ft to 4x4ft, with custom control options and ceiling integration compatibility.

Cleanroom Flooring

Our flooring solutions include ESD vinyl sheet, epoxy resin coatings, and raised antistatic floors. All flooring types meet cleanroom chemical resistance, slip resistance, and durability standards. We offer various colors, finishes (matte/gloss), and edge treatments to support GMP and ISO compliance.

Flush-Mounted Windows

Designed for seamless integration with wall systems, our flush windows use double-layer tempered glass with anti-fog, UV-blocking, and optional anti-static coatings. Frames are pressure-tight, easy to clean, and compatible with GMP or FDA guidelines. Multiple sizes and shapes (rectangular, circular) available upon request.

Air Vents & Grilles

Air supply and return grilles are available in aluminum or SUS304 stainless steel with powder-coated or anodized finishes. Our vents integrate pre-filters, HEPA boxes, and adjustable dampers. They are engineered for uniform airflow and cleanability—ideal for ISO Class 5–8 environments.

Integrated Air Shower System

Our modular cleanrooms can be seamlessly equipped with custom-built air showers to enhance contamination control at key entry points.Modular Compatibility:designed to integrate perfectly with our wall panels and door systems, air showers are pre-engineered for quick installation and smooth connection.

How Customization Works

We follow a clear 4-step process to design your cleanroom within budget:

1

Requirement Gathering

Tell us your industry, room size, and cleanliness level.

2

Concept Design

We provide layout, airflow plan, and estimated cost.

3

Quote & Adjustment

Refine options to meet function and budget.

4

Confirmation

Finalize design and prepare production.