Clean Room For Laboratory

The concentration of airborne particles have to be kept as low as possible. The air purity is usually monitored very closely. Here, human beings seem to be the biggest safety hazard for particle contamination. Moreover, machines and assets in a cleanroom are able to completely contaminate optical components, for example,we can use cleanroom in classical optics and micro optics.

APPLICATION

Laboratory

SIZE

51150.1 sqft

CLEANROOM CLASS

Class10000 / ISO7

Cleanliness Level

The cleanliness of the clean room is very important. According to the purpose of the laboratory, the cleanliness level can be divided into ISO 5, ISO 6, ISO 7 or ISO 8. Clean rooms generally implement two-level isolation, which is achieved through biological safety cabinets, negative pressure isolators, positive pressure protective clothing, etc.

Ventilation And Exhaust System

In order to prevent laboratory personnel from inhaling toxic and harmful gases, clean rooms need to be equipped with ventilation and exhaust systems, including fume hoods, exhaust hoods and other facilities. The types of ventilation systems include negative pressure ventilation, positive pressure ventilation or mixed ventilation, which need to be determined according to the design and purpose of the laboratory.

Decoration Material Selection

The decoration materials of the laboratory should be easy to clean, dust-free and corrosion-resistant, such as stainless steel, PVC, ceramic tiles, epoxy resin, etc. The floor materials should be non-slip and anti-static, the wall materials should be corrosion-resistant and easy to clean, and the ceilings, doors and windows should be made of dust-free and easy-to-clean materials.

Air Flow And Pressure Control

The airflow in the laboratory should flow from the clean area to the non-clean area, usually in the form of upper delivery and lower exhaust. The pressure difference between areas of different clean levels should be at least 5Pa, and the pressure difference between the clean room and the outside should be at least 10Pa. The air flow design should be reasonable to ensure air quality.

PICTURE SHOW

Clean Room Equipment

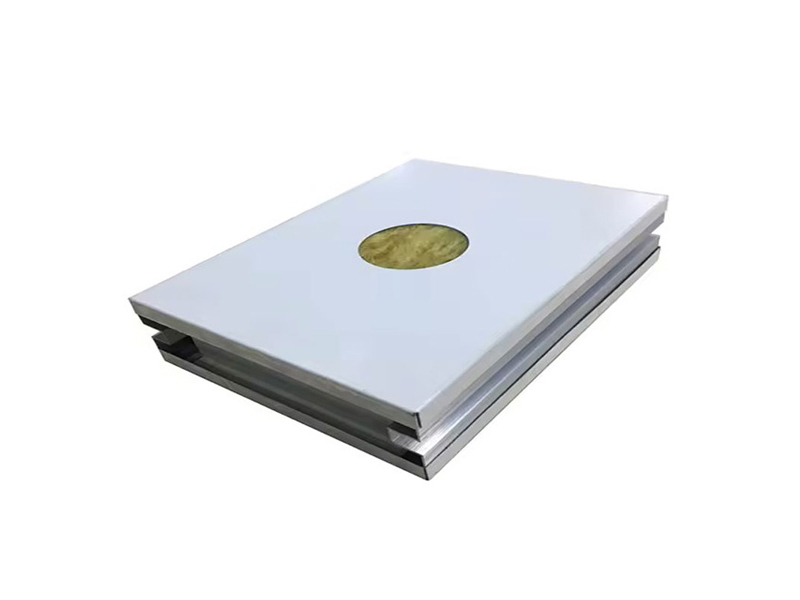

Sandwich Panel

Clean Wardrobe