About Us

Committed to becoming a modular cleanroom solution provider that brings happiness to employees and satisfaction to customers

Professional and Expert Cleanrooms Contractor

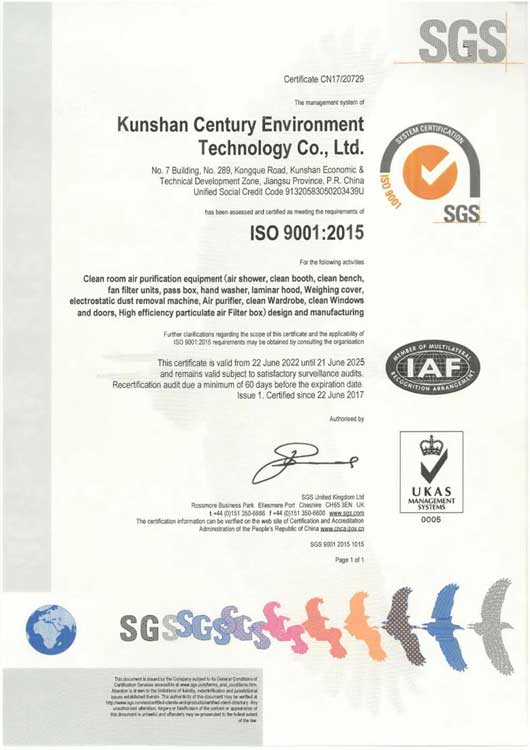

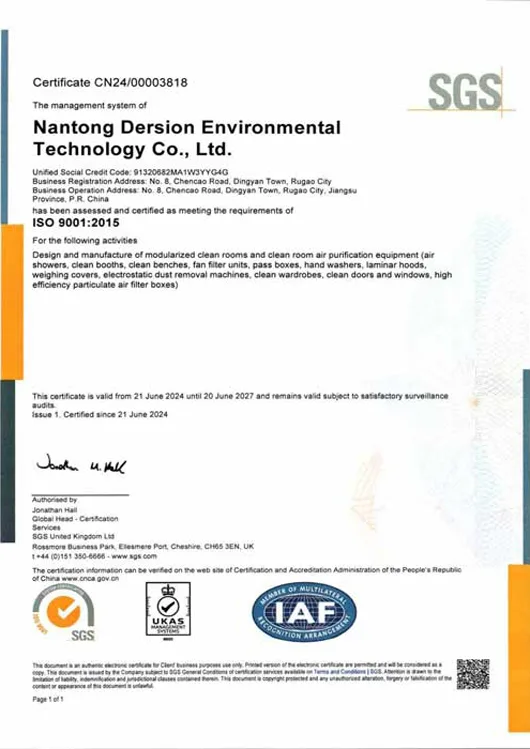

Dersion was founded in 2005. The factory is located in Nantong China, covering an area of more than 20,000 square meters of modern plant. Dersion has always adhered to the high quality and innovation, and is committed to being the leader of clean room equipment and related services. Dersion has been providing customers with "modular, intelligent and energy saving" clean room solutions. Now we got nearly 60 national patents passed the ISO9001:2015 quality management system certification of SGS . Dersion's products have been exported to 50 countries around the world. We are close to Nantong port and Shanghai port , with convenient transportation and logistics.

Our Factory

Why Choose Us

Reason For Choosing Us

20 years of project experience, 300+ customer cases covering optics, electronics, medical and other industries

Provide free floor plan design and 3D renderings, and customize solutions that better meet your needs

In-house production for fast delivery, stable quality, and cost control

Development History

DERSION is a leading cleanroom manufacturer in China, offering professional cleanroom construction and installation services for various industries.

2005

Serving small and medium-sized enterprises

2009

Serving Apple's supply chain customer groups

2015

The first company in China to propose "modular clean room"

2019

Upgrading smart factories and advocating high-standard production

2025

Cultural upgrading, brand reconstruction, sustainable development

Production Workshop

From precision machining to on-site installation, we have a complete production chain and strict quality control process. Our professional project team provides you with full-process services from solution design to after-sales delivery, ensuring that every clean room project is implemented stably.

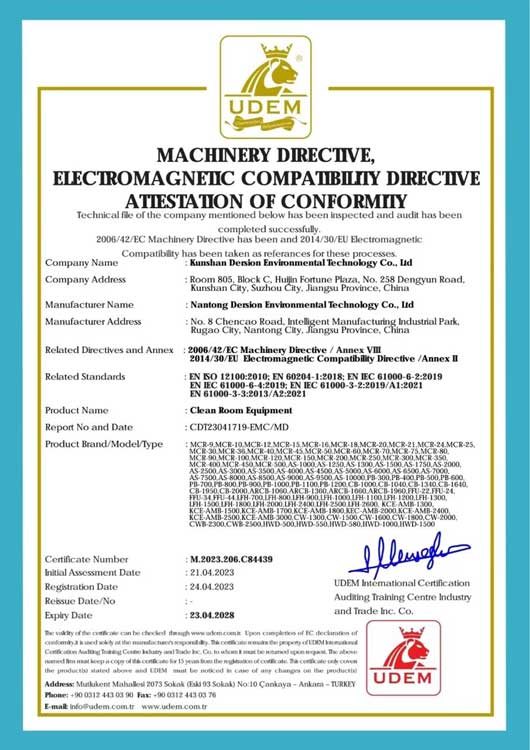

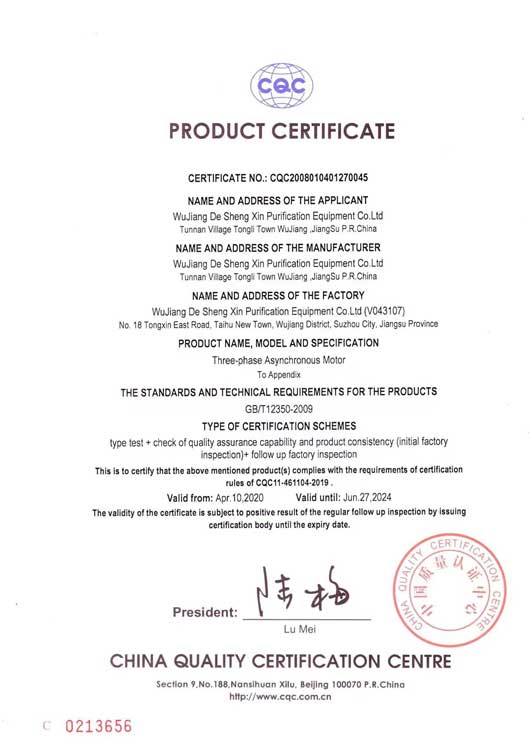

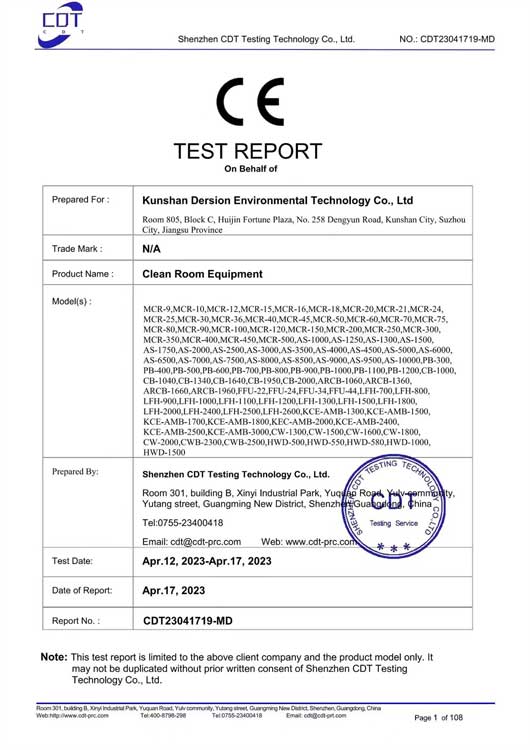

Cleanroom ISO Certification

OUR CERTIFICATE

Corporate Culture

Meet Our Team!

Our team of cleanroom contractors ensures that every project meets the highest industry standards.

Factory Production Process

Step 1:Precise Measurements, Custom Designs

Our process begins with meticulous measurements and tailored designs to meet the unique requirements of each project. Utilizing advanced CAD software, we ensure that every specification is accurately captured, allowing for a perfect fit and optimal functionality. Customization options are available to align with specific aesthetic and functional needs.

Step 2: Incoming Material Control and Scientific Management

We implement rigorous incoming material control to ensure that only high-quality materials are used in production. Our scientific management system tracks and monitors material properties, ensuring consistency and reliability. This step is crucial for maintaining the integrity and performance of the final product.

Step 3: Precision Blanking to Ensure Molding Quality

Precision blanking is performed using state-of-the-art machinery to achieve exact dimensions and clean edges. This process is essential for ensuring the quality of the molding, as it directly impacts the fit and finish of the components. Our technicians are trained to maintain the highest standards during this critical phase.

Step 4: Precise Bending and Welding to Improve Aesthetics

Our skilled craftsmen employ precise bending and welding techniques to enhance the visual appeal and structural integrity of the product. Attention to detail during this stage ensures that the final product not only looks great but also performs flawlessly under various conditions.

Step 5: Dust-Proof, Moisture-Proof, and Drop-Proof Packaging

To protect the product during transit, we use specialized packaging that is dust-proof, moisture-proof, and drop-proof. This ensures that the product arrives in pristine condition, ready for installation. Our packaging solutions are designed to withstand the rigors of shipping and handling.

Step 6: Provide Professional Installation, Commissioning, and After-Sales

Our team of experts provides professional installation and commissioning services to ensure that the product is set up correctly and functions as intended. We also offer comprehensive after-sales support, including maintenance and troubleshooting, to guarantee customer satisfaction and long-term reliability.

Step 7: Dust-Free Assembly and Strict QC Testing

Assembly is conducted in a controlled, dust-free environment to prevent contamination and ensure the highest quality. Each product undergoes strict quality control (QC) testing to verify that it meets our stringent standards. This step is vital for delivering a product that is both durable and dependable.

Step 8: ISO and SGS Authoritative Certification, Quality Assurance

Our commitment to quality is underscored by our ISO and SGS certifications. These authoritative certifications provide assurance that our processes and products adhere to international standards. We continuously strive to uphold these certifications through rigorous quality assurance practices.

Make a Difference Today

Get Free Clean Room Quotes !

Whether it’s design, construction or optimization, our team of experts will provide you with a free customized quote. Based on your needs, we will provide the most suitable cleanroom solution, ensuring that it meets industry standards and your special requirements.